Nitinol

A shape memory alloy undergoes a phase transition changing from one crystal structure to another at a specific temperature, with substantial forces in theprocess. The most common shape memory alloy is Nitinol (Nickel Titanium Naval Ordinance Lab). Variations in the ratio of nickel to titanium and variations in processing create different nitinol characteristics.

Nitinol can exhibit a shape memory effect, where it transitions from one crystalline structure to another, and moves with substantial force in the process, upon the application of heat at a temperature specific to the alloy.

Super-elastic nitinol, shares the ability of the alloy to stretch up to 30% of its length without permanent deformation, a highly unusual characteristic for a metal.

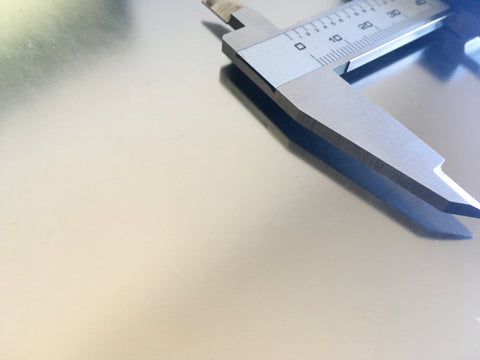

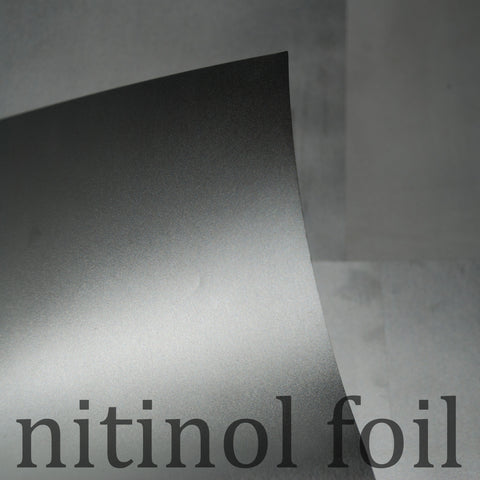

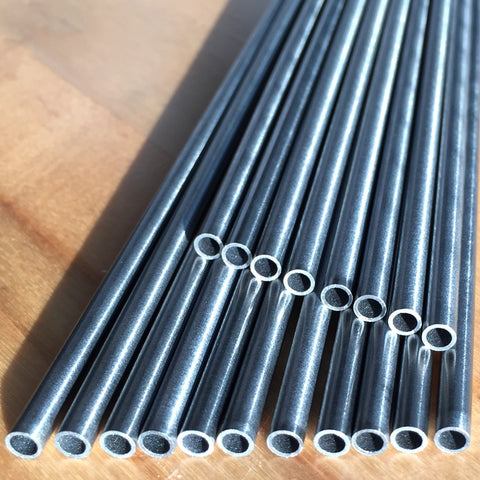

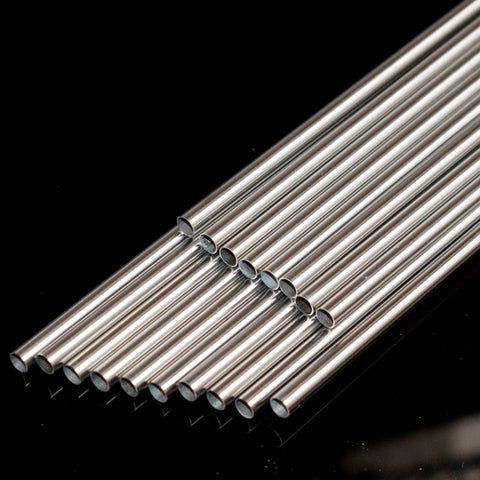

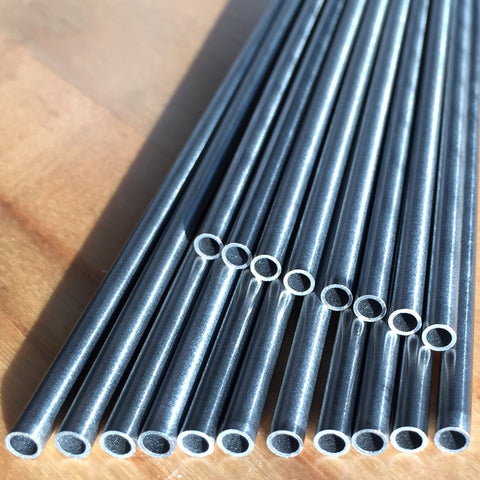

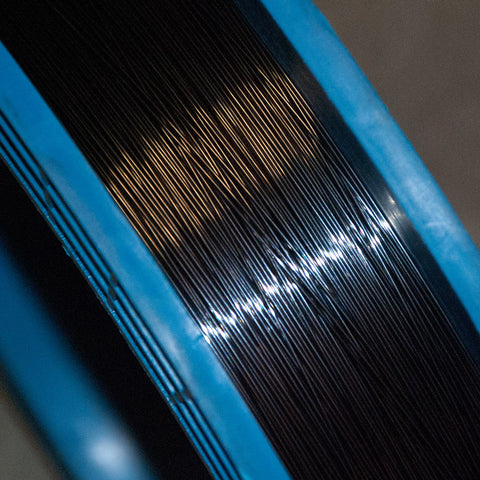

Nexmetal Corp stocks both superelastic and shape memory nitinol in wire, sheet, and tube form. For most projects, we recommend wire as it is the least expensive and most versatile form. In comparison, sheet allows you to create 3-dimensional forms that move, and tube allows you to pump heated/cooled fluid directly through the tube for mess-free, highest efficiency activation. Nitinol can be welded in an oxygen-free environment (use shielding gas).

Many clients have custom needs. We consult, produce and deliver. Contact us for custom work involving springs, tubes, sheet or wire - most projects are completed in less than 30 days, order minimums are affordable, and the results are magical.

![Nitinol Shape Memory Alloy Sheet; 1mm (0.04") thick; Af 80-90°C [176-194°F]](http://nexmetal.com/cdn/shop/products/DSC_0468_e1598282-1790-458d-9686-2e1a8293029e_large.jpg?v=1547961929)