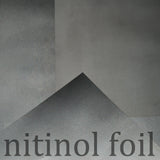

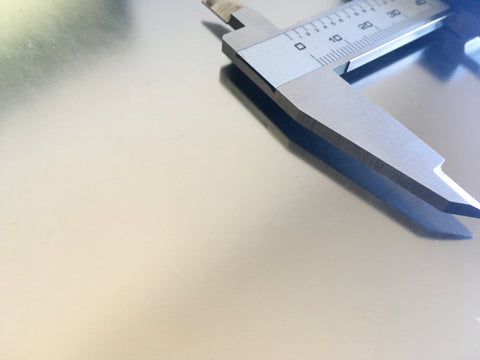

NiTi • Nitinol Shape Memory Alloy Foil; 0.12mm thick; AF 45°C

Nitinol Foil - 0.12mm

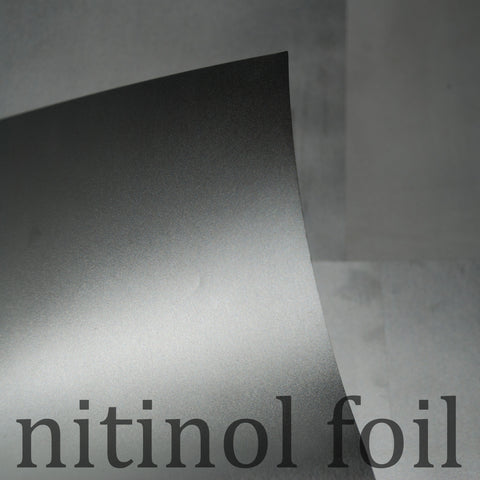

Sheet will return to flat when heated. Additional heat treatments are recommended after cutting out your desired part to improve performance. Heat treatment directions will be provided.

Nitinol foil can be used for either its movement characteristics, chemical resistance, puncture resistance, or other needs where the features of nitinol are needed in a foil.

You can order it directly on this page in 1 inch increments, up to a maximum sheet size of 4.75 x 35.2.

1x2 and 2x2 inch nitinol foil sheets, activated using hot water from the faucet.

Nitinol nickel titanium inter-metallic (superalloy) with a 50ºC phase transition temperature.

The foil is very strong and puncture resistant. It will return to original / trained shape when heated to approx. 50ºC or above. Heating past 100ºC is not recommended or necessary unless you are setting a new shape.

Transition temp 45ºC. Simple ordering. Worldwide shipping.

Characteristics

The video below depicts 2mm diameter NiTi 80ºC transition phase dropped in 95ºC hot water. The ending is 1/16 speed. Turn up the sound.

Transition Temperatures

Nitinol changes its crystalization pattern at more than 1 temperature point. The stoichiometric ratio of Ni to Ti, impurities, and post-processing determine the mechanical characteristics of your nitinol.

All transition temperatures are specified in Celsius ºC. The temp indicated is an approximation of where the alloy begins to undergo the crystalline transformation. It occurs over a fairly wide temperature range. So, a 40C rated wire will perform faster and stronger at 80C.

At room temperature, an 80C wire will be substantially more malleable and soft to your fingers, the 40C will be more difficult to bend, and the 15C will feel like spring steel. The 15C will react to a heat source up to 80C, while 80C NiTi is more suitable for exposure up to 150C. The 15C will be malleable at and below freezing temperatures.

Return Transition Phase

A common question concerns the ability of the alloy to transition back to its cold shape upon cooling (double dipping). This alloy will exhibit a slight mechanical effect upon cooling, however it does not exhibit nearly the same level of energy as upon heating. The effect is most noticeable in the 15C wire however is mildly present in all of these alloys.

We Also Recommend

![Nitinol Shape Memory Alloy Sheet; 1mm (0.04") thick; Af 80-90°C [176-194°F]](http://nexmetal.com/cdn/shop/products/DSC_0468_e1598282-1790-458d-9686-2e1a8293029e_large.jpg?v=1547961929)