Nitinol SMA Shape Memory Alloy Wire

Select the diameter, unit of measure, and activation temperature. Wire below this temperature is soft. Wire above this temperature gets hard and assumes its memorized shape (straight unless reprogrammed).

If all you want is springy wire, select the temperature a little below your intended operation temperature. For example, room temperature (21°C) superelastic = 15°C or 0°C wires operate best.

Wire ships continuous. Example: Qty 5, increment: meters = 5 meters uncut continuous wire. Global delivery DHL Express $35 - 3 to 4 days World Wide.

USA orders $35 Next Day Air - $7.90 First Class Mail

Looking for 2-way linear actuator wire? Available here.

Nitinol nickel titanium superalloy heat activated muscle wire 0.1 - 3mm. Transition temps ranging from -20ºC to 80ºC (-25ºF to 180ºF). In stock. Simple ordering. Worldwide shipping.

For custom sizes, open a chat or email us and we'll send a quote.

Choosing the right nitinol wire

Select the wire that is ideal for your temperature. Consider:

- Activation temperature - the higher temperature that nitinol is subjected to, the faster it will respond. A 40C wire will respond faster to boiling hot water than 80C wire. So for a faster response, use a lower transformation temperature wire.

- Ambient temperature - higher temperature nitinol wire will return to martensite (soft) faster in warmer environments. A 60C wire will get soft earlier than 40C wire when cooling down in a room that is 30C ambient. In cycle applications, this will allow the cycle to repeat sooner.

- Diameter - thicker diameter wires exert substantially more force, but take much longer to heat up and cool down, resulting in longer cycle times. Subsequently you may consider using multiple strands of thinner wire.

You can also order a sample variety pack of commonly used nitinol wires here in different thicknesses and temperatures to find the one best for your needs.

Be sure to also try the 2-way linear actuator wire. It is available here: https://nexmetal.com/products/nitinol-linear-actuator

Characteristics

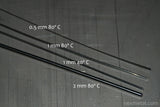

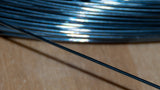

The wire has a lustrous titanium color (dark grey) with a bluish oxide tint on its surface. When freshly cut, the inner core is nickel white. Nitinol is very abrasion resistant and has self-healing properties, so the wire is quite hard to cut and kink. It does not require any special handling or protections from oxidation or moisture, and is non-toxic. The best way to damage it is by overheating it, so if you are using electricity instead of hot water to activate it be sure to use a current limiting circuit. Video in slo-mo, ending is at around 16x slow, notice the interesting sound.

Transition Temperatures

Nitinol changes its crystalization pattern at more than 1 temperature point. The stoichiometric ratio of Ni to Ti, impurities, and post-processing determine the mechanical characteristics of your nitinol.

All transition temperatures are specified in Celsius ºC. The temp indicated is an approximation of where the alloy begins to undergo the crystalline transformation. It occurs over a fairly wide temperature range. So, a 40C rated wire will perform faster and stronger at 80C.

At room temperature, an 80C wire will be substantially more malleable and soft to your fingers, the 40C will be more difficult to bend, and the 15C will feel like spring steel. The 15C will react to a heat source up to 80C, while 80C NiTi is more suitable for exposure up to 150C. The 15C will be malleable at and below freezing temperatures.

Return Transition Phase

A common question concerns the ability of the alloy to transition back to its cold shape upon cooling (double dipping). This alloy will exhibit a slight mechanical effect upon cooling, however it does not exhibit nearly the same level of energy as upon heating. The effect is most noticeable in the 15C wire and NiTiCu, however it is mildly present in all of these alloys, and can be emphasized with proper training.

Purchase Options

- Select your desired unit of measure, and use the quantity selector to choose your ideal length in metric, imperial or by weight.Choose your desired diameter. 0.5mm is 24 gauge, 1mm = 18 gauge, and 2mm = 12 AWG.

- Finally select your transition temperature. Not all sizes are available in all transition temperatures at all times. If checking out is not possible, email us for a custom quote.

- When you order multiple quantities we will cut one long section off of the pictured roll so you can procure uncut sections and cut later as you please.

We Also Recommend

![Nitinol Shape Memory Alloy Sheet; 1mm (0.04") thick; Af 80-90°C [176-194°F]](http://nexmetal.com/cdn/shop/products/DSC_0468_e1598282-1790-458d-9686-2e1a8293029e_large.jpg?v=1547961929)